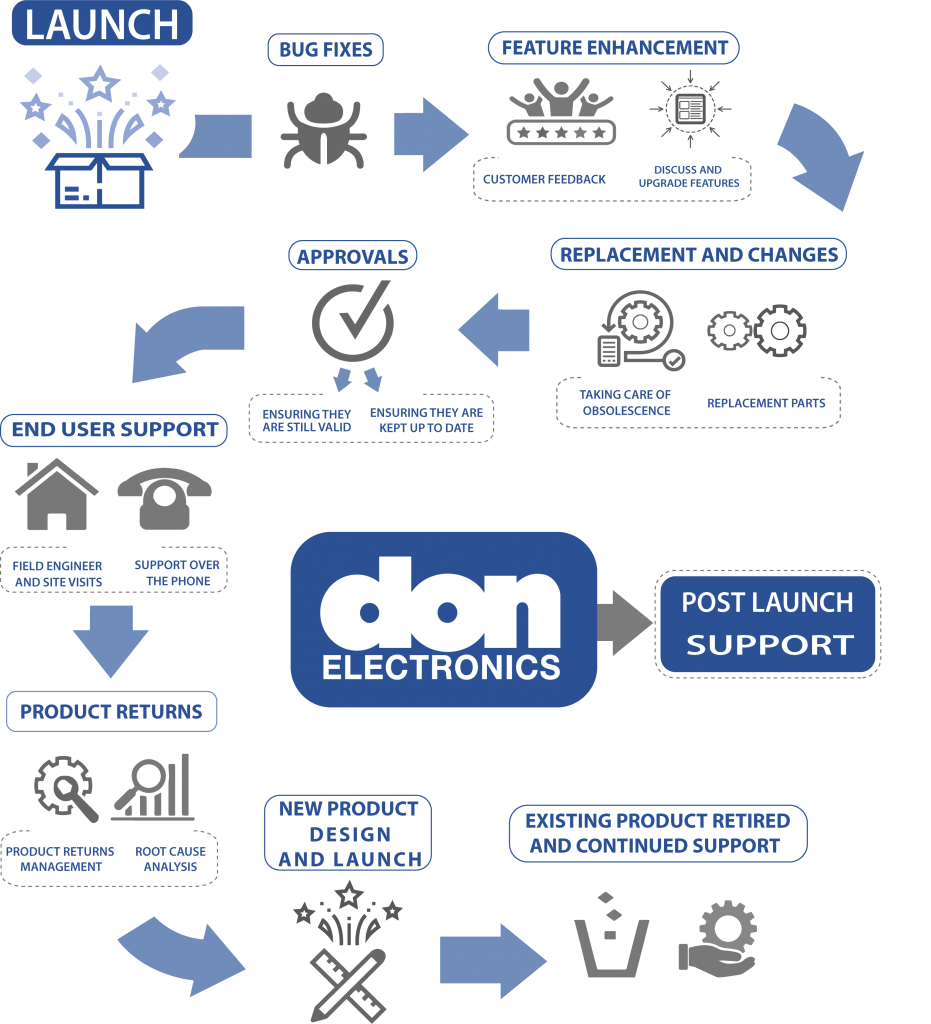

Don Electronics has extensive experience in designing products for Hazardous Location environments (in particular dust and gas) and more than 90% of our products have been approved by third party bodies including IECEx, CSA, NEPSI Ex, EAC Ex, CCC and INMETRO as well as North American Ordinary Location approvals. Our team has worked across a multitude of high performing industry sectors such as bulk material handling and petroleum processing and ensured these products met country specific approvals to allow for global distribution. We provide continuous support throughout our full product development cycle including post launch support to keep products up to date with the ever-changing technological environment and lower our partners future expenses.

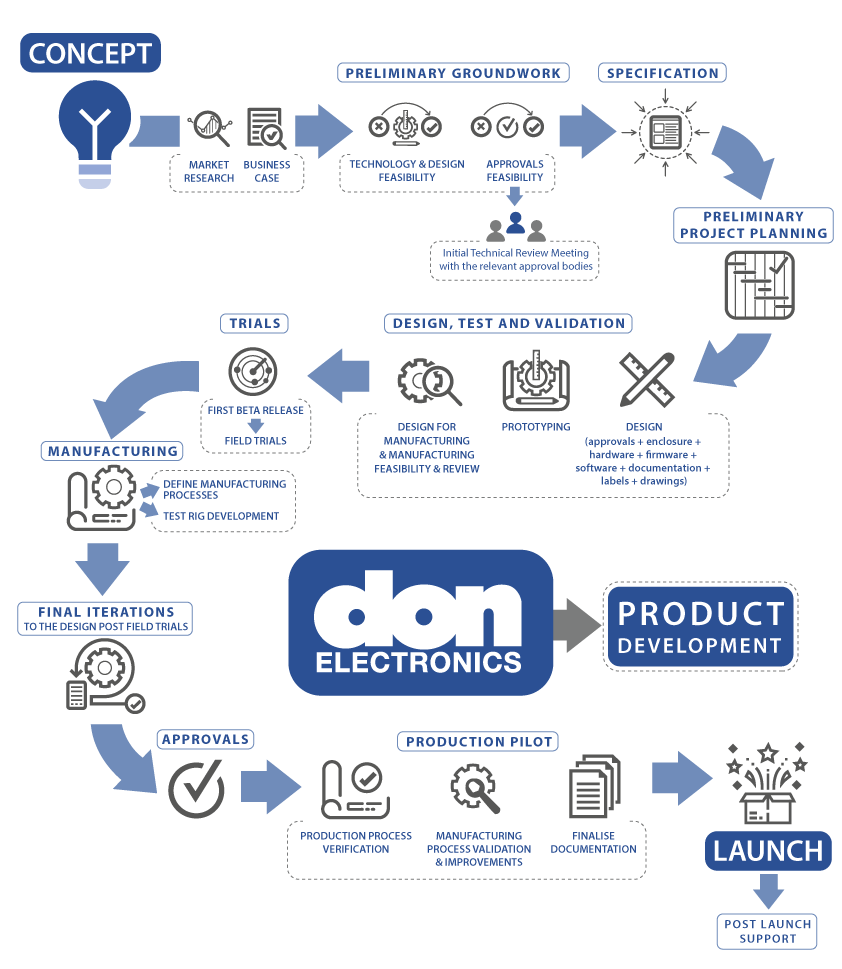

Our Design Team at Don Electronics will take your concept and work with you through our Product Development Cycle.

Our in-house team have access to software and equipment that gives us full control of the design process and the ability to work to deadlines that suit your needs. Our range includes:

- Project Control and Management software

- PCB Design software applications

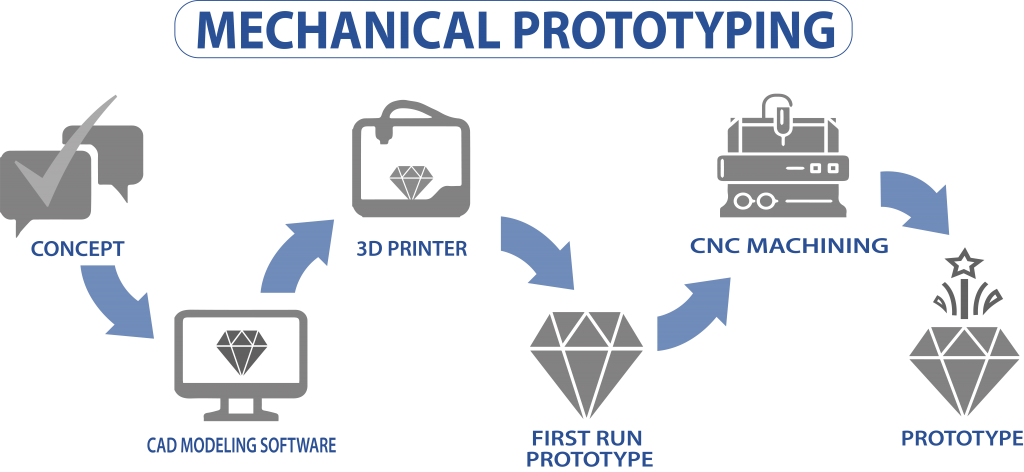

- 2D/3D CAD/CAM, Modelling

- Microcontroller programming/firmware utilities

- GUI scripting software

Throughout our history we have gained valuable insight into how specific industries tackle individual problems and we take that knowledge to support developments across all industries and product types. Our experienced design team’s capabilities include:

- Complete concept to manufacturing design services for sensors and control devices for installation in Dust and Gas hazardous environments

- Embedded software architecture

- Embedded programming of microcontrollers like Microchip’s PIC, AVR, STM32

- Real-time operating systems

- Networking and associated protocols

- PLC Programming

- Graphical User Interface including displays, key and touch pads

- IoT and wireless products

- Cloud connectivity and processing

- App Development to complement the hardware

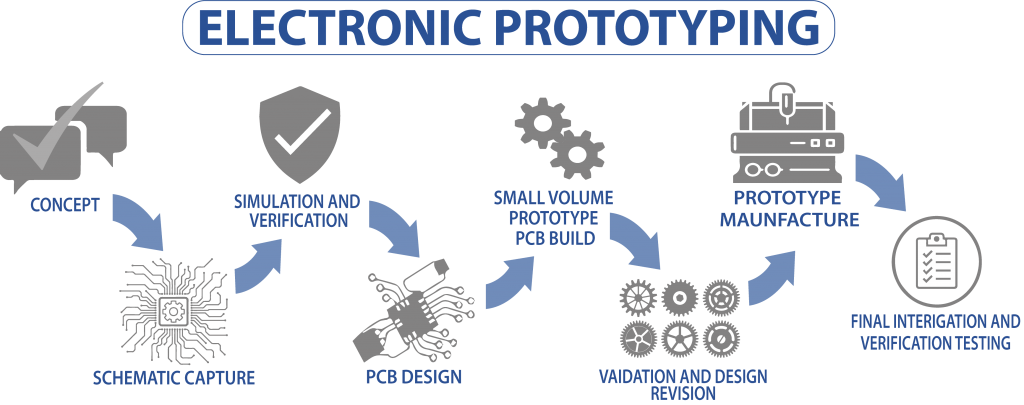

- Hardware and PCB Design Services

- Integration with custom hardware, hardware verification and bring up

- System integration

- Verification, validation and field testing

- Design for manufacturing

- High skills on hand soldering for prototyping or small batch productions

- Capabilities for fast prototyping using in-house pick and place machine and reflow oven

- Prototyping and mock-up demonstrations

Please do not hesitate to contact us so we can help you in getting your concept to reality.